The common definition of a framework is an underlying structure on which expansion can be built, with increasing utility.

This concept can be applied to a physical structure; for example a supporting aluminium framework. A set of ideas, the 'framework' of our cultural values of intellectual decisions; or a web framework, a comprehensive guide on how to develop and maintain software and code.

Since 2004, modulan has embodied these principles in developing our products for data centres around the world. Our "Framework" continues to operate on these three planes.

Find out more about the solutions and benefits modulan delivers to its data centre customers.

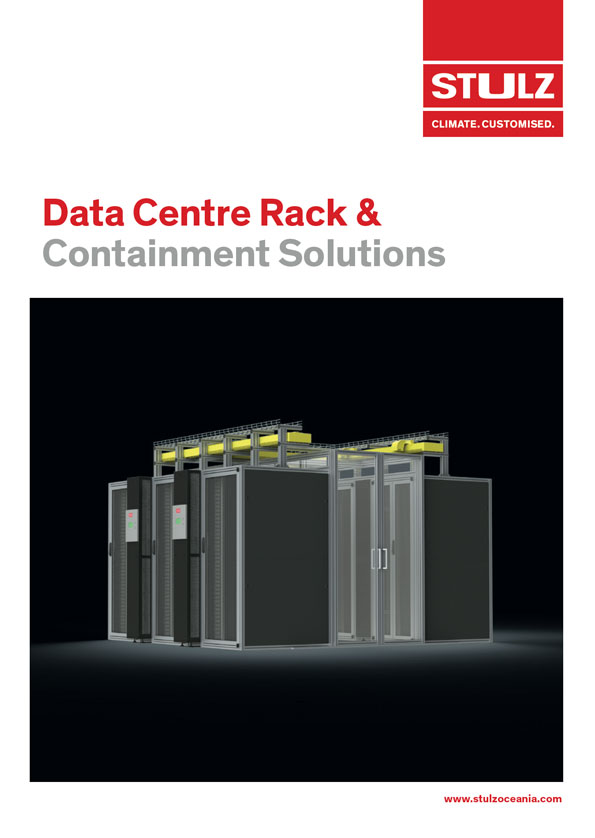

We provide solutions for every type of data centre

The benefits of modulan solutions

Our products are high quality and flexible

Find out more about modulan

Through the customisation of modulan’s solutions we can design and implement your vision to perfectly suit your needs. No longer are you at the mercy of standard rack manufacturers, modulan offers you the ultimate in creativity and flexibility for the data centre.

Our products offer unlimited flexibility, are lightweight and have the highest stability with clean open finishes. The aluminium profiles offer surprising possibilities for mounting accessories from all renowned suppliers. Solid connections allow for professional assembly of cable management, equipment and power supply.

Our systematic approach allows us to design custom-made solutions which meet your individual needs and wishes.