CyberAir 3PRO CW

The benchmark of flexibility and energy efficiency

The CyberAir 3PRO CW controls the conditions in the data center with the utmost precision, reliability and energy efficiency. Because STULZ technology leads the field, it can exploit potential savings to the full while still ensuring maximum reliability. No matter how different data centers may be, the CyberAir 3PRO CW is a chilled water air conditioner both flexible and made to measure: it is available in 11 sizes with various air conduction methods.

Product Overview

Most important benefits

- Maximum cooling capacity with a minimal footprint

- Highly efficient air conduction (Airflow Efficiency Ratio)

- Maximum potential savings with Indirect Dynamic or Direct Free Cooling

Most important features

- Chilled water air conditioning systems available with integrated and external fan unit

- 2 cooling systems (CW, CW2), 11 sizes, various air conduction methods, different heat exchangers

Most important technical data

- Cooling capacity (kW): 22 – 260

- Air conduction: Upflow, Downflow, Downflow with outlet front/back/down

- Maximum cooling capacity with a minimal footprint

- Highly efficient air conduction (Airflow Efficiency Ratio)

- Maximum potential savings with Indirect Dynamic or Direct Free Cooling

- Optimized for operating conditions based on the ASHRAE recommendation

- Flexibility for individual customer solutions

- Highest EER values due to maximum size of heat exchangers and filter surfaces

- EC fans of the latest generation reduce power consumption

- Compact design facilitates chilled water air conditioner’s transport and installation

- Individual unit tests at the STULZ test center

- Available with integrated and external fan unit

- 2 cooling systems (CW, CW2), 11 sizes, various air conduction methods, different heat exchangers

- CW standby management, differential pressure control and filter control management

- Control based on the supply air, return air, room air or server inlet temperature

| Cooling capacity (kW) | 22 – 260 |

| Air conduction | Upflow, Downflow, Downflow with outlet front/back/down |

| Airflow volume (m³/h) | 7,500 – 46,200 |

| Dimensions | Height (mm): 2,495 – 2,915 Widths (mm): 950 – 3,350 Depths (mm): 890 – 1,040 |

| Cooling systems | Chilled water (CW/CW2) |

Need more information?

Download our brochure!

All details about CyberAir 3PRO CW

Energy efficiency & reliability - CyberAir 3PRO CW

New size specifically for large and hyperscale data centers

Free Cooling

Two different Free Cooling methods are used, depending on how the outside air is used. If the outside air is conveyed directly inside the building, this is Direct Free Cooling. If the outside air does not penetrate the sensitive interior of the building, this is Indirect Free Cooling. Both methods offer advantages but entail certain challenges. We individually check which version best matches your needs, requirements, and intended use - and which solution provides you with the best value over the life of the system.

Direct Free Cooling

The CyberAir 3PRO CW precision air conditioning system with Direct Free Cooling air conditions Data Centers up to 90 % more economically than conventional compressor cooling systems. Direct Free Cooling exploits the potential of outside temperatures to air condition the data center using the cool outside air. Via the CyberAir 3PRO CW, the outside air, which has been treated by filter systems, gets directly into the server room.

CyberAir 3PRO CW units with downflow air conduction can be equipped with the FreeCool Plenum Free Cooling box. The FCP design with the dampers on top is a flexible construction that takes up no extra space for the chilled water air conditioner. With this option, Free Cooling is automatically combined with the chiller system's compressor cooling in three variable stages, to suit the outside temperature and cooling needs, ensuring that maximum savings are always exploited to the full.

Learn more about Direct Free Cooling

Indirect Dynamic Free Cooling

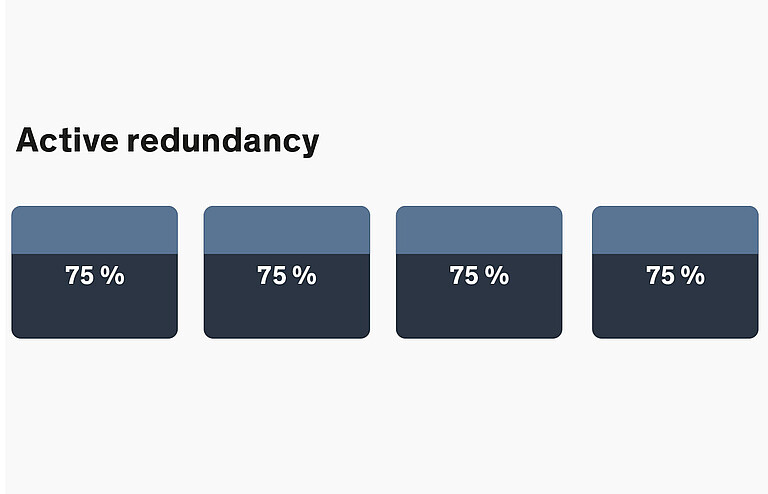

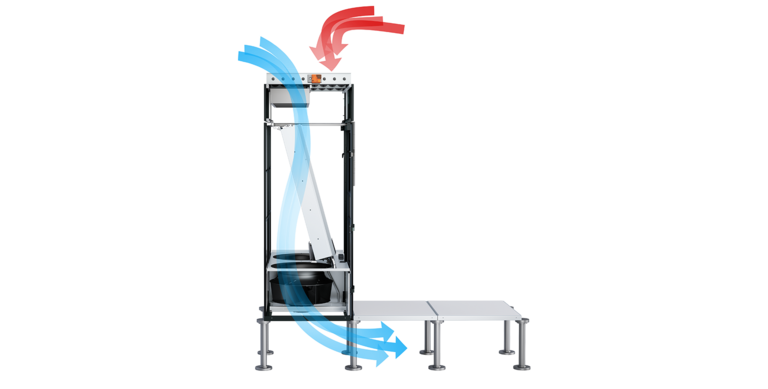

Fans in the raised floor

Optimized unit design for maximum potential savings

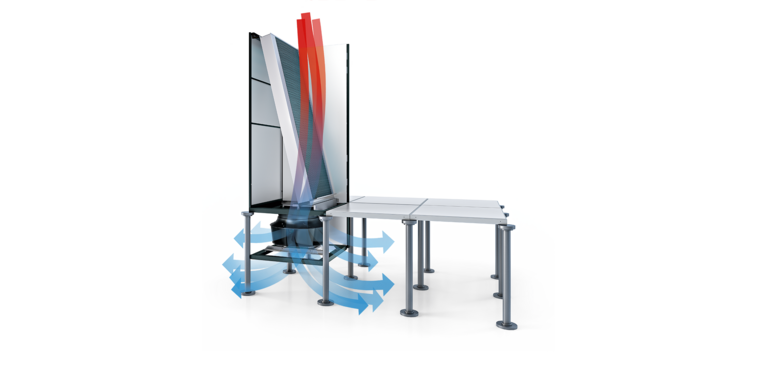

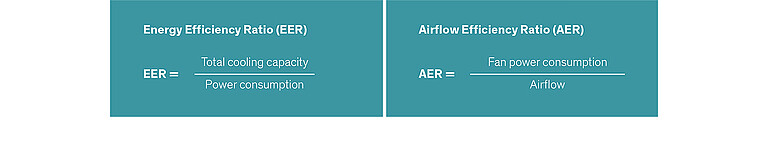

The design of our units means that STULZ precision air conditioning units boast maximum EER values and the lowest AER (Airflow Efficiency Ratio) values, and therefore achieve air conduction with maximum efficiency. The AER describes the ratio of the fan power consumption to the airflow. ASR air conduction (fans integrated in the raised floor), in particular, hugely reduces fan power consumption by ensuring minimal turbulence and changes in airflow direction, for energy savings that you will notice straight away.

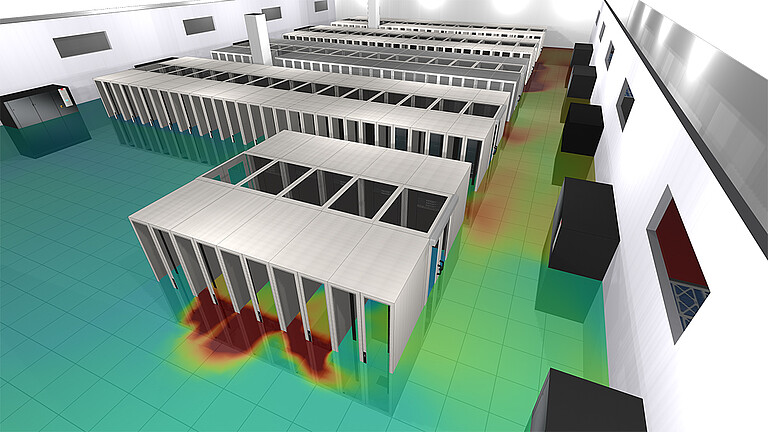

CFD simulation

Comprehensive control over all relevant factors is vital to achieve optimal performance and efficiency in a data center. STULZ contributes to this goal by providing the CFD (Computational Fluid Dynamics) service for data centers, using its unique fluid dynamics expertise at the product level to make the CFD simulation more accurate at the application level.

Precise temperature regulation

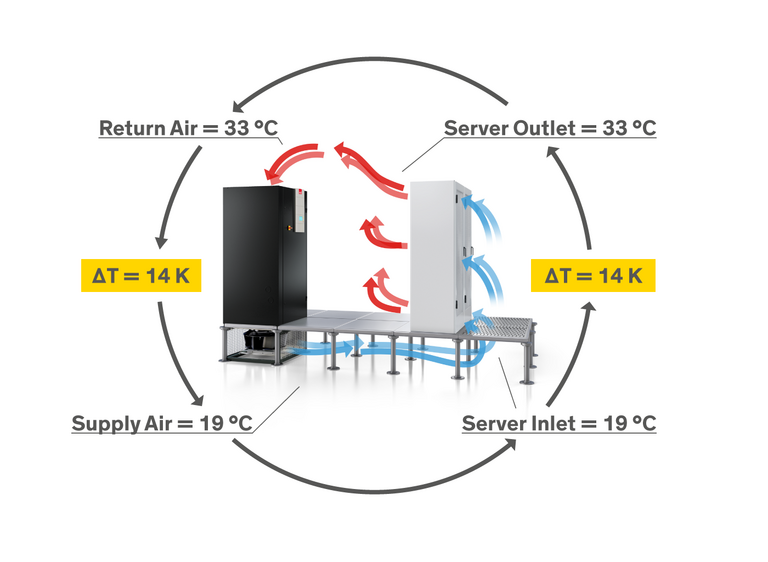

Delta T

The air-side difference in temperature between the air inlet and outlet of server cabinets and air conditioning systems is known as ΔT. To ensure optimum operation and the greatest possible savings on running costs, it is vital that the ΔT of the air conditioning units is adapted precisely and efficiently to the ΔT of your server cabinets.

Our dynamic control enables ΔT to be adapted to changing IT requirements, ensuring maximum energy efficiency during operation.

Learn more in our blog-article "Delta T – The air-side temperature difference"

Temperature profile

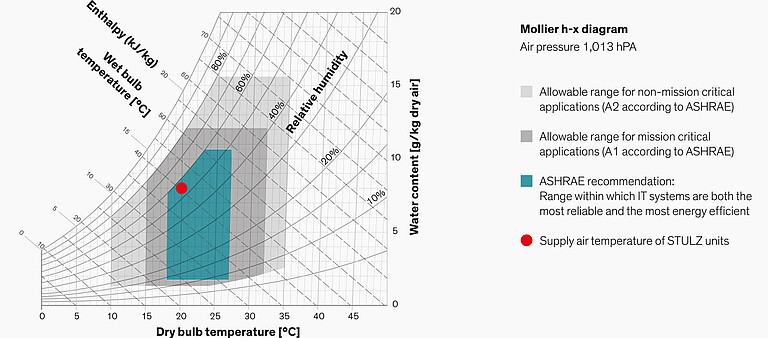

Optimum supply air conditions for reliability and maximum efficiency

To cool your data center as efficiently as possible without compromising on reliability, ASHRAE has published a recommendation for the air temperature at the server inlet. We have been developing chilled water air conditioning units for mission-critical applications - where even tiny malfunctions can have serious consequences - for decades now. Not only that, we have always focused on energy efficiency, and because of this, the supply air temperatures of our units lie within ASHRAE's recommended range.

EC fans

RadiCal EC fans of the latest generation

- GreenTech EC technology

- Significantly higher air output

- Over 10% lower power consumption

- Reduced noise

- Optimized airflow

- Improves the AER of CyberAir 3PRO CW units

- Latest motor generation

- Impellers made of high-tech composite material for increased fan power density

- Long lifetime

Pressure independent control valve

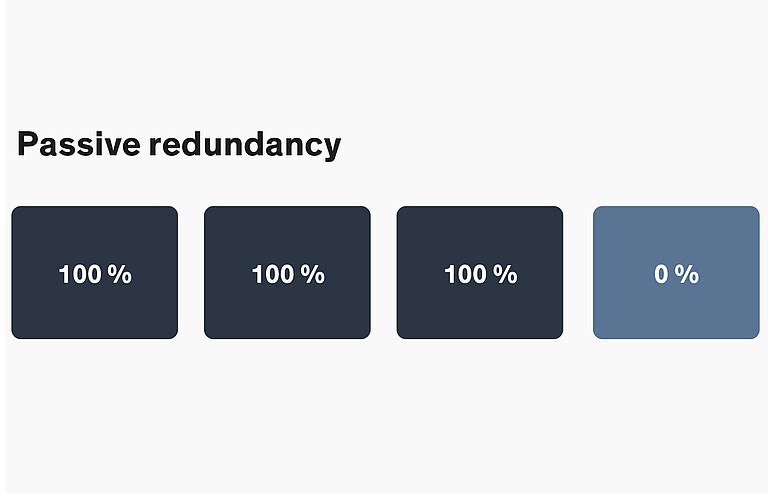

Standby management

Control and monitoring

In order to meet the highest standards of reliability and usability, STULZ develops the control system in-house, ensuring that software, hardware and air conditioning units are perfectly harmonized.

- High flexibility: Project-specific software development and optimization

- Optimized usability: Touch display offers clear menu navigation and intuitive handling of the controller.

- Maintenance-friendly: Plug-and-play installation and optimized control parameters simplify maintenance tasks

- Maximum reliability: Redundancy management, integrated standby management with backup operation, differentiated warning and alarm system

- Energy management: Supports energy demand optimization for interconnected systems, operation of several air conditioning units in parallel

- Monitoring: Direct BMS interfaces on the controller, support for all relevant BMS protocols and a compact data point list simplify commissioning.

Service and maintenance

As a company with locations across the globe, we offer everything you need in the extremely dynamic world of information technology – plus professional advice in the right place at the right time.

Our trained and experienced sales and service partners are located in over 140 countries. The resulting proximity to our customers allows fast response times. In addition, regular training courses and an active exchange of information ensure high quality and an extensive knowledge of all our products. This way, you can be sure your products are in the best hands and get the right maintenance – all over the world.

Test Center

In our state-of-the-art, 700-square-meter Test Center with its various climate chambers, we can perform a variety of tests on precision air conditioning units and chillers. During the development of the CyberAir 3PRO CW, we were able to test and optimize it under all climatic conditions encountered around the world.

In addition, we offer you the opportunity to book a witness test in our Test Center. This allows you to have the desired air conditioning system tested according to your exact specifications, creating transparency and providing you with information about your system’s performance and energy consumption.

Read more about our Test Centers

Flexibility

Climate. Customized.

From standard units to fully customized solutions

The ability to offer such a wide range to customers is the embodiment of our philosophy, "Climate. Customized.". Size, design, air conduction, system or control: CyberAir 3PRO CW is a model of adaptability and the room air conditioners can be precisely adapted to your individual requirements. In addition, a variety of options and equipment versions are available to achieve the optimum result.

Learn more about Climate. Customized.

Upflow, Downflow and Raised Floor

Various air conduction systems

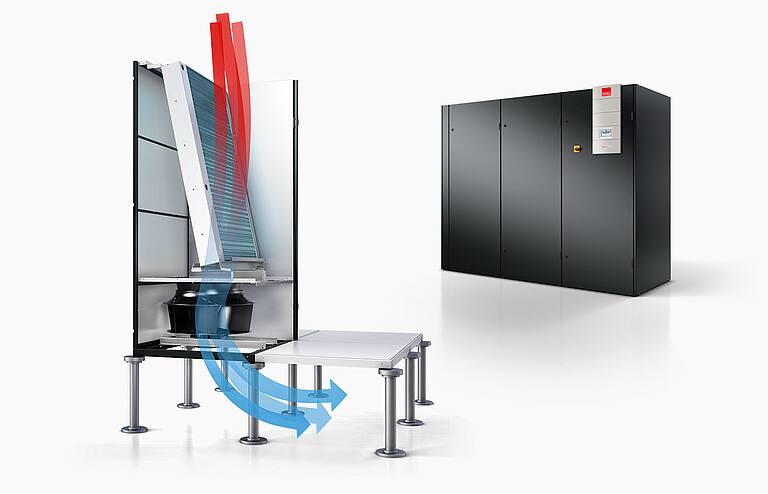

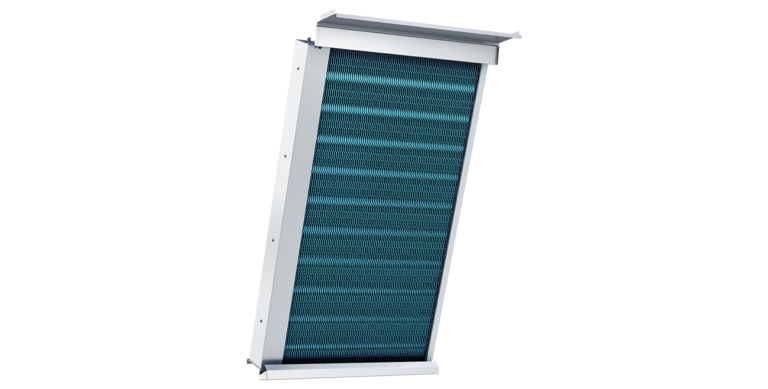

Heat exchangers

Options for data center cooling

The numerous different options and possible equipment enable you to perfectly adapt CyberAir 3PRO CW chilled water air cooler units to your requirements.

Cooling Systems

STULZ offers individual system solutions adapted precisely to your project requirements.

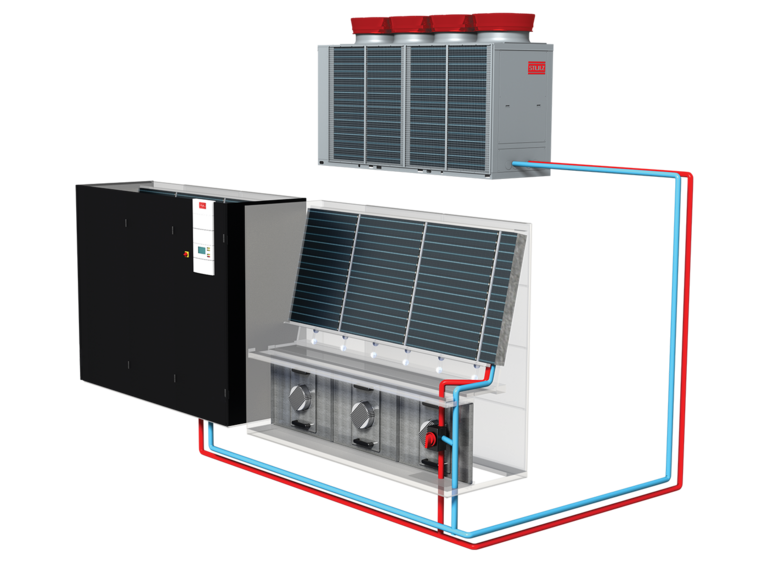

CW system

CW system: Liquid cooled system

CW units manage without a refrigerant circuit of their own, but require separate chilled water generation. The room air conveyed by the fan flows through the direct cooling unit, which transfers heat to the water/glycol mixture. A chiller removes the heat from this water/glycol mixture. The air conditioning unit and the chiller are connected to one another by a closed water/glycol circuit.

CW2 system

CW2 system: Liquid cooled system with built-in redundancy

High-reliability systems frequently require a second, independent chilled water supply. Therefore, in the CW2 system two redundant CW systems are integrated in a single air conditioning unit, saving valuable space in the Data Center.